|

|

|

|

Taylor K-6530ChemWorld is a distributor of Taylor Technologies Test Kits and Reagents. Order directly online and save today.

REAGENTS:

- 1 x R-0833 DI Water

- 1 x R-0834 pH Soaker Solution

- 1 x R-0868-25C Conductivity Solution 2500 uS (1273 ppm NaCl)

- 1 x R-1099-04 Buffer Solution pH 4.0

- 1 x R-1099-07 Buffer Solution pH 7.0

- 1 x R-1099-10 Buffer Solution pH 10.0

COMPONENTS:

- 1 x 5844 Instruction

- 1 x 6530 Meter, TechPro IITM Model TPH1, 0-14 pH, 0-19.99 mS

CAUTION: When this instrument is exposed to extreme heat or cold,

reading stability is affected. Allow the plastic case to

cool or warm to stablize reading. Failure to do so will

void warranty (see Temperature Extremes).

WARNING: pH sensor must be hydrated at all times with R-0834

pH Storage Solution. If R-0834 pH Soaker Solution is

not available, a strong KCl solution, a colorless pH 4.0

buffer, or a saturated solution of table salt and tap

water may be used temporarily. Warranty void if sensor

is not properly maintained.

pH

CONDUCTIVITY/TDS MEASUREMENT

1. Remove pH sensor protective plug on top of instrument and rinse

both sample wells three times with sample to be measured.

2. Refill both sample wells with sample to be measured.

3. Press pH key to read pH and/or temperature.

Press COND/TDS key to read conductivity/TDS and/or temperature.

4. Rinse both sample wells three times with R-0833 DI Water

(or tap water) when finished with the instrument. Cover

pH sensor with R-0834 pH Soaker Solution and replace

pH sensor protective plug.

INSTRUMENT CALIBRATION

NOTE: For calibration, buffer solutions and conductivity

standard solution should be approximately room

temperature (25 degrees C/77 degrees F).

pH

1. Remove ZERO CAL and GAIN CAL cap plugs on bottom of instrument.

2. Remove pH sensor protective plug on top of instrument and rinse

sample well three times with R-1099-07 Buffer Solution pH 7.0.

3. Refill sample well with R-1099-07 Buffer Solution pH 7.0.

4. While pressing the pH key, adjust the ZERO CAL control with finger

until display reads 7.0.

5. Rinse sample well three times with either R-1099-04 Buffer

Solution pH 4.0 or R-1099-10 Buffer Solution pH 10.0.

NOTE: If pH of sample will be above pH 7.0, use R-1099-10

Buffer Solution pH 10.0.

If pH of sample will be below pH 7.0, use R-1099-04

Buffer Solution pH 4.0.

6. Refill sample well with selected buffer solution.

7. While pressing the pH key, adjust the GAIN CAL control with finger

until display agrees with selected buffer solution.

NOTE: If meter will not calibrate, the sample well needs

additional rinsing or fresh buffer solution, or the

pH sensor is bad and needs to be replaced.

8. Replace ZERO CAL and GAIN CAL cap plugs.

9. Rinse and cover pH sensor with R-0834 pH Soaker Solution

and replace pH sensor protective plug.

CONDUCTIVITY/TDS

1. Remove COND CAL cap plug on bottom of instrument.

2. Rinse sample well three times with R-0868-25C Conductivity

Solution 2500 uS (1273 ppm NaCl) or other standard solution.

3. Refill sample well with standard solution.

4. While pressing the COND/TDS key, adjust the COND CAL control

with finger until display reads the value of the standard solution.

5. Repeat steps 3 and 4 to verify the setting.

6. Replace COND CAL cap plug.

7. Rinse sample well with R-0833 DI Water (or tap water).

CHANGING FROM CENTIGRADE TO FAHRENHEIT

NOTE: Degrees F to degrees C is the reverse.

1. Dry instrument THOROUGHLY.

2. Remove the 4 bottom screws and carefully open instrument.

3. Locate dip switch labeled "TEMP COMP" on the circuit board.

4. Set switch number 4 to the off position.

5. Carefully turn instrument over and press the pH key. The displayed

reading will be in Fahrenheit (although "degrees F" will not be shown).

6. Replace bottom, ensuring the sealing gasket is installed in the

groove of the top half of the case. Tighten screws securely.

CHANGING FROM CONDUCTIVITY (uS) TO TDS (ppm NaCl)

NOTE: TDS (ppm NaCl) to Conductivity (uS) is the reverse.

1. Dry instrument THOROUGHLY.

2. Remove the 4 bottom screws and carefully open instrument.

3. Locate dip switch labeled "TEMP COMP" on the circuit board.

4. Set switch number 3 to the on position.

5. Carefully turn instrument over and press the COND/TDS key.

The displayed reading will be in ppm NaCl.

6. Replace bottom, ensuring the sealing gasket is installed

in the groove of the top half of the case. Tighten screws securely.

BATTERY REPLACEMENT

1. Dry instrument THOROUGHLY.

2. Remove the 4 bottom screws and carefully open instrument.

3. Carefully detach battery from circuit board. Replace

with 9 volt alkaline battery.

4. Replace bottom, ensuring the sealing gasket is installed

in the groove of the top half of the case. Tighten screws securely.

TEMPERATURE EXTREMES

Solutions in excess of 71 degrees C (160 degrees F) should not

be placed in the sample well; this may cause damage. The pH sensor

may fracture if the TPH1 Meter temperature is allowed to be

below -10 degrees C (14 degrees F). Care should be exercised not to

exceed rated operating temperature. Leaving the TPH1 Meter in a

vehicle or storage shed on a hot day can easily subject the instrument

to over 66 degrees C. (150 degrees F). This will void the warranty.

CLEANING ELECTRODES AND pH SENSOR

CONDUCTIVITY OR TDS

The sample well should be kept as clean as possible. Flushing

with clean water following use will prevent buildup on electrodes.

However, if very dirty samples--particularly scaling types--are

allowed to dry in the sample well, a film will form. This film

reduces accuracy. When there are visible films of oil, dirt, or

scale in the sample well or on the electrodes, use a foaming

non-abrasive household cleaner. Rinse out the cleaner, and your

TPH1 is ready for accurate measurements.

pH

The unique pH sensor in your TPH1 is a nonrefillable combination

type which features a porous liquid junction. It should not be

allowed to dry out.

If it does, the sensor can sometimes be

rejuvenated by first cleaning the sensor well with a liquid spray

cleaner such as WindexTM or FantasticTM and rinsing well. Do not scrub

or wipe the pH sensor.

Then use one of the following methods:

1. Pour a HOT salt solution approximately 60 degrees C (140 degrees

F), preferably potassium chloride (KCl) solution--HOT tap water

with table salt (NaCl) will work fine--in the sensor well and

allow to cool. Retest.

OR

2. Pour DI water in the sensor well and allow to stand for no more

than 4 hours (longer can deplete the reference solution and

damage the glass bulb). Retest.

If neither method is successful, sensor must be replaced.

"Drifting" can be caused by a film on the pH sensor bulb. Spray

a liquid cleaner such as WindexTM or FantasticTM into the sensor

well to clean it. The sensor bulb is very thin and delicate. Do

not scrub or wipe the pH sensor.

pH SENSOR

REPLACEMENT

Order model RPG. Include the model and serial number of your

instrument to ensure receiving the proper type. Complete installation

instructions are provided with each replacement sensor.

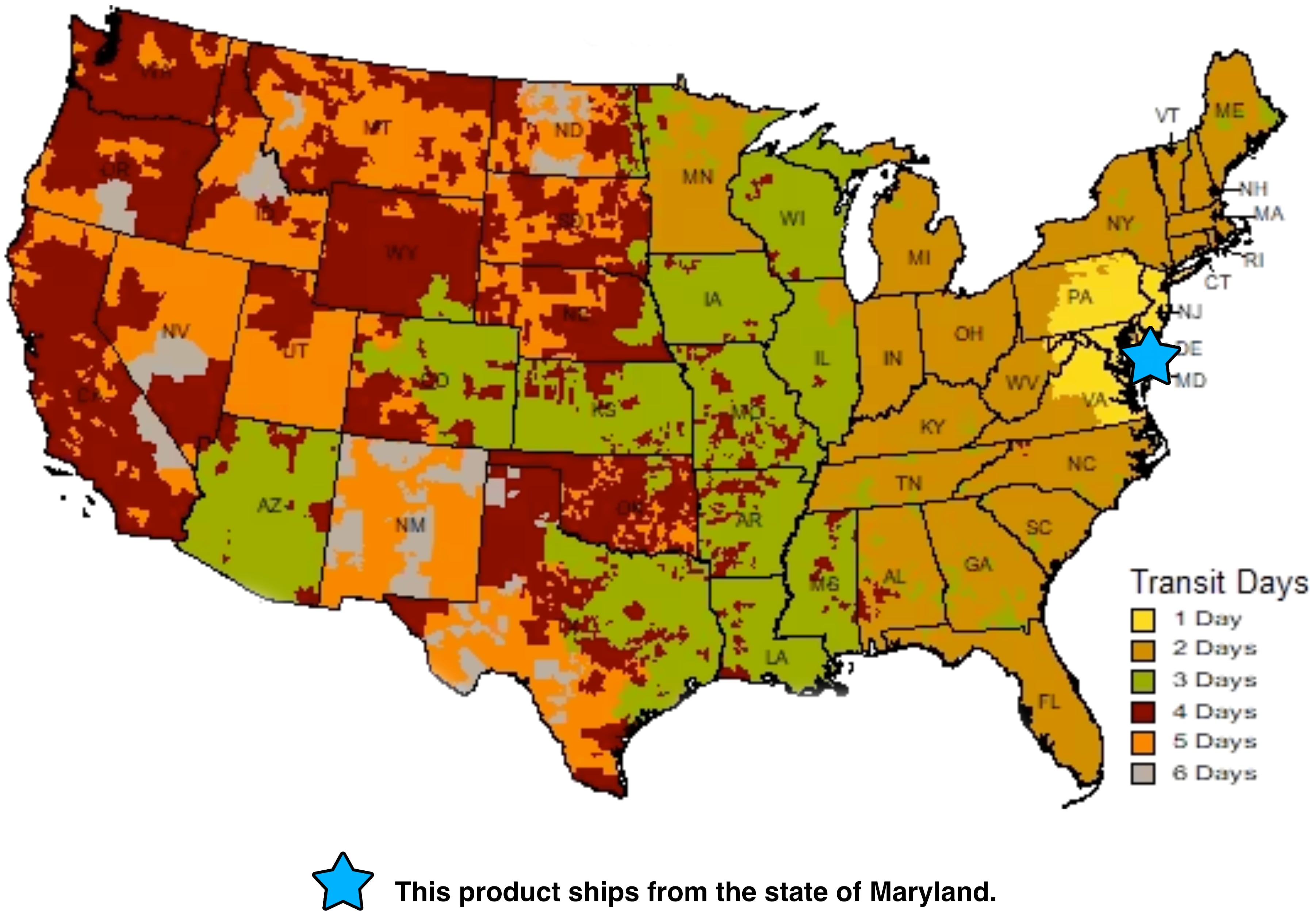

This product ships within approx. 5 to 7 business days from the state of Maryland. Listed below is the shipping transit time for 2024. UPS transit map - This product only ships UPS. We can not ship this product via Fedex or USPS.

- We can ship internationally.

- We can not ship this product to a PO box.

- If the product is Haz mat. It can not can not ship this via Air.

You will receive the tracking info after the order ships within 48 to 72 hours. We do not offer expedited shipping for this product.

If you can not order online, call in your order at 800-658-7716.

|

|

|

|

|

|

|