|

Liquid Sulfamic AcidChemWorld Q-CID SL is a liquid blend of Sulfamic Acid with a highly effective inhibitor designed for the cleaning and maintenance of water systems. The product is particularly effective at removing iron and precipitated hardness deposits and is recommended for use where worker safety considerations are of prime importance. ChemWorld also provides a powder form of Sulfamic acid. This product is used in both cooling and boiler water applications.

When used for cleaning water systems, ChemWorld Q-CID SL is added to the system to be cleaned at the typical rate of 10 to 20%, depending on the severity of the deposits to be removed. It is then recirculated for 2-8 hours. The heating of the solution will speed the reactions and assist in the removal of the deposits. During the cleaning, the acid strength may be monitored with the readings indicative of either when the cleaning is complete or the acid is spent. After cleaning, draining and flushing the system, it should be filled with a neutralizing solution and circulated for at least an hour to ensure any pockets which may have trapped acid solution are neutralized. Then, when drained and flushed, the system should be immediately treated to passivate newly exposed metal surfaces

ChemWorld Q-CID SL may be toxic by ingestion and because it is highly acidic, is corrosive to human tissues. Do not take internally. If ingested, drink at least two (2) glasses of water and get medical attention. Contact with eyes causes severe irritation or burns. If eyes are contacted, immediately flush with clear water for 15 minutes and get medical attention. For skin contact, wash with soap and water. Wear goggles and rubber gloves when handling. Immediately change and launder contaminated clothing before reuse. For additional information, see the Safety Data Sheet provided with this product.

If this sounds like too much work consider gradual cleanup of boiler scale using ChemWorld 1394.

For all new cooling tower startups, consider our ChemWorld 101 Cooling Startup Kit. This kit includes the following:

- One 5 gallon pail of ChemWorld Q-ALK-PC - This product is required to clean the debris and greases prior to startup.

- One 5 gallon pail of ChemWorld 1334 - ChemWorld 1334 is scale and corrosion control cooling tower chemical. After startup, you can perform testing of your water hardness and alkalinity and we can tune in your exact chemical for long-term protection.

- One 5 gallon pail of ChemWorld 56 - ChemWorld 56 is a 12.5% sodium hypochlorite product that is required to kill bacteria. This is the cheapest easiest product to get your system up and going, you can convert to tablets or a stabilized bromide product after startup.

- One LakeWood 140 Cooling Tower Controller - You will need to set the controller to feed and bleed the cooling tower water to maximize cycles and to minimize chemical usage rates. An optional dual biocide water treatment can be implemented after startup. This is model 1239597 (which is board mounted unit that has the flow assembly on the left).

- One 1167435 Cooling Tower Blowdown Valve (1" NPT) - This will be required when the cooling tower calls to release cooling tower water.

- Two Stenner 45MHP10 Adjustable Head Pumps - One pump is required for the corrosion/ scale prevention chemical and for the biocide. Each pump is rated to 100 psi, which should be enough to feed the chemical into the system. The ideal spot to feed the chemical is into the return header of the cooling tower. These Stenner Pump kits come with chemical injection valves that will allow for quick injection of each chemical into the sidestream water loop that is used to monitor the cooling tower conductivity.

- One complete CWTK-200 Cooling Water Treatment Test Kit. This kit contains every test you will need to set up and fine tune your water treatment program.

- One Chemical Metal Test Station Cabinet - You need to keep your test kits and lo sheets in one clean location. This test kit is ideal for cooling towers.

For new steam boiler startups, consider purchasing our Steam Boiler Startup Kit.

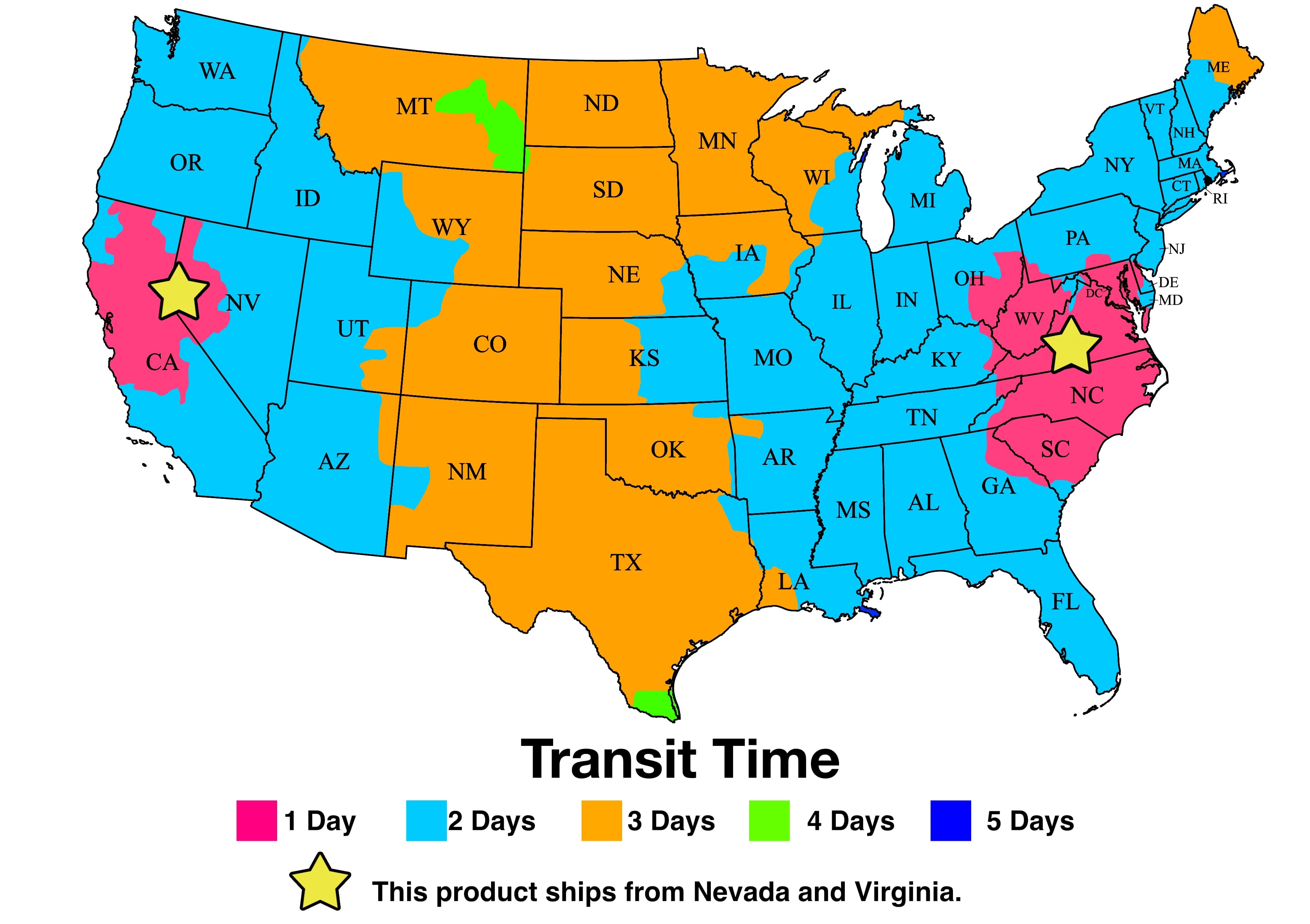

This product is manufactured to order per ISO specifications. Lead time on production is 4 to 7 days. Free shipping transit time in business days as of May 2023 (After Production).  Remember production time is 4 to 7 days. This map illustrates transit time in business days as of May 2023.You will receive your tracking number within a week after ordering. Remember production time is 4 to 7 days. This map illustrates transit time in business days as of May 2023.You will receive your tracking number within a week after ordering.

|

|

|