|

Steam Boiler Chemical5, 15, 30, and 55 Gallons of All in One Boiler Chemicals. Choose between an amine or non-amine product.

- Improves boiler reliability and cleanliness.

- All in one product for ease of use.

- Sulfite removes dissolved oxygen.

- Utilizes polymers for excellent control of hardness and iron deposition.

- The polymer is stable over a wide range of temperatures and pressures.

- Feed straight from the container. No mixing required.

- ISO manufactured.

- Product quality insured up to $2,000,000.

- Easy sulfite droplet testing control method.

- Amine product (1197) minimizes corrosion to your condensate pipes.

- ChemWorld 1287 is USDA and FDA approved for use in food regulated facilities.

- ChemWorld 1197 contains DEAE, which is approved per FDA 173.310 for use in the preparation of steam when the steam will contact food or food packaging. FDA limits the amount of DEAE to 15 ppm in the steam, and not for use in milk or milk products. There are no FDA regulations specifying maximum amine concentrations of indirect steam humidification systems. There are regulations regarding air contaminants, such as OSHA 29 CFR 1910.1000, but these do not directly apply to the steam and are difficult to calculate and test for.

How to use:

ChemWorld 1287 and 1197 are all-in-boiler chemicals. They are designed to make boiler chemical feeding and testing easy.

- Download our boiler testing log sheet and use it as a reference.

- Feed the chemical as far back into your steam boiler system (into the feed water tank, DA tank, or feed water line). This will ensure the metal as far back in the system is protected against corrosion.

- The chemical control is limited by sulfite residual. If you have a good softener, the phosphate in the products will prevent scaling. If you have a poor working softener, you must maintain a 7 to 1 ppm Phosphate to Hardness in your boiler water. With a good softener, the phosphate levels will not be a limiting factor in this product, rather it is more important to monitor the hardness levels within the boilers as a reference.

- Keep a minimum of 20 ppm of sulfite residual (or use ASTM standards) on all active and idle boiler systems to reduce the risk of oxygen corrosion within your boiler. If you have an excess product, it will raise your conductivity levels but will have no adverse effect on your boiler. You are just wasting chemical, water, and thermal energy within the water.

- If your boiler conductivity is too low, you are probably blowdown to much water or grossly overfeeding the chemical. Reduce blowdown and reduce chemical dosage and wait a few days. Allow the water to cycle up again within the boiler. Remember the purpose of your steam boiler system is to reuse water. Target a conductivity of 2,000 to 3,000 umhos (most steam boilers). For mid to large size steam boilers, we always recommend automation with a LakeWood Conductivity Controller. Using a Myron Meter is an easy way to verify the conductivity of your controller and boiler water.

- This chemical will add additional conductivity to your boiler water. Overfeeding will have no adverse effect on the boiler, but it will waste chemicals and you will blowdown excess water. Conductivity is a measurement of dissolved solids, dissolved gases, and suspended solids.

- Add more product as needed based on sulfite residual in your boiler water, but remember to keep your conductivity in range or your sulfite reading will be irrelevant. Use a Sulfite Test Kit to verify your residual.

- This product needs to be added daily, bi-weekly, or weekly depending on how your systems operate. In theory, the more frequently you add it, the less of the product you will use.

- The purpose of the chemical is to prevent corrosion and scale prevention. As long as you have any sulfite in the boiler water, it means you have no dissolved oxygen in the boiler water.

- If you have any other questions, please email us at [email protected]. Remember to keep it simple. This is an easy boiler chemical to use as long as you get it into the system, you maintain proper conductivity levels within the boiler, you have a good operating softener, and you periodically check that sulfite is in the boiler. Do not over complicate it.

For new steam boiler startups, consider purchasing our Steam Boiler Startup Kit.

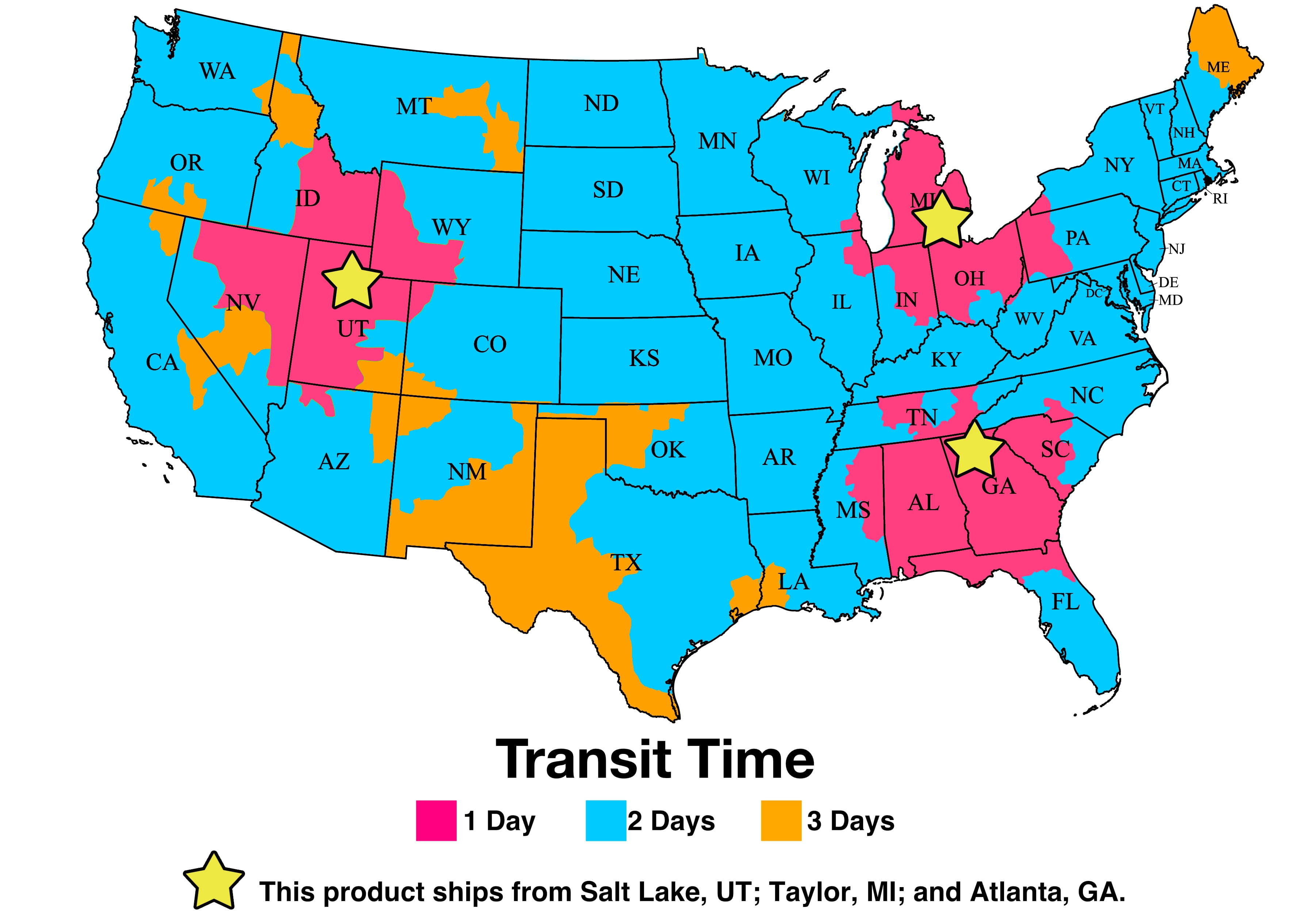

ChemWorld 1287 is Stocked & Shipped daily from Atlanta, Georgia; Detroit, Michigan; and Salt Lake City, Utah.Daily shipping cut off time is generally 1 pm, based on the local time zone for same day shipping. If you need this product to ship today, please indicate so in the notes section upon check out. We will email mail you ASAP if we can meet your demands.

Figure 1- USA FedEx Residential and Ground

Transit Time Map

Notes:

- We only ship via FedEx Ground. No UPS or USPS.

- We can not ship to PO boxes.

- This map illustrates service schedules in business days as of May, 2023 for FedEx Ground shipments.

- ChemWorld is not responsible for delays due to weather or FedEx transit issues. Please take this into account when ordering.

Overnight / Expedite Shipping:

- Orders must be received by noon.

- We only ship FedEx expedite shipments. No UPS or USPS.

- To calculate your costs, log into your FedEx Account. Origin zip code is 30144 or 84119.

Directions for Overnight Shipping:

- Order must be placed by noon.

- Order as normal through the website.

- If you have a FedEx Account number, enter it in the notes section during ordering with your exact shipping requirements (Next Day 8:30, Next Day 10:30, Next Day 20:00, Fedex 2 AM, or FedEx Express Saver). You are done. We will email you ASAP.

- If you do NOT have a FedEx Account number, we offer overnight delivery for this product. The cost is $170 for Next Day 10:30 AM per pail. Enter your order as normal and enter your 3 or 4 digit security code in the notes section with your shipping requirements. You are done. We will email you ASAP.

If it is later then noon, email us at

[email protected] with your request. We will contact you ASAP. You can also call in the order at 800-658-7716 and reference exactly what you need. We will contact you. ChemWorld 1197 is manufactured to order per ISO specifications. Lead time on production is 4 to 7 days. Product ships from Virginia and Nevada.

- Since the product is manufactured to order we can not provide expedited orders.

See transit times map below for

ChemWorld 1197:

Free shipping transit times map

(after production of ChemWorld 1197).

Remember production time is 3 to 5 days. This map is transit time. You will receive your tracking number within a week.

|

|

|