|

|

|

|

1.5% Isothiazolin

The most common concentration of Isothiazolin in water treatment is 1.5% solution. This product may ship from a variety of suppliers depending on your state or country.

Isothiazolin is used in recirculating cooling water systems and closed loop systems to control microbial growth. The product is effective over a wide pH range against the microorganisms typically found in these systems.

- Good on aerobic bacteria and nitrifiers, poor for anaerobic SRB, fair on fungi and algae.

- Dosing: 60 to 80 ppm to the recirculating water, max slug dose is 883 ppm. Most water treatment applications base dosage on bacteria dipslide results.

- Use dipslides to monitor performance.

- Excellent broad spectrum microbiocide.

- Effective over the range of pH;s found in typical cooling systems.

- Does not adversely affect cooling water treatment components.

- Non-foaming.

- Compatible with halogen biocides.

For cooling water applications, feed the chemical directly into the main header of the water with a

retractable kynar corporation valve or into a side stream loop with a kynar injection quill.

For new cooling tower startups, consider our ChemWorld 101 Cooling Startup Kit. This kit includes the following:

- One 5 gallon pail of ChemWorld Q-ALK-PC - This product is required to clean the debris and greases prior to startup.

- One 5 gallon pail of ChemWorld 1334 - ChemWorld 1334 is scale and corrosion control cooling tower chemical. After startup, you can perform testing of your water hardness and alkalinity and we can tune in your exact chemical for long-term protection.

- One 5 gallon pail of ChemWorld 56 - ChemWorld 56 is a 12.5% sodium hypochlorite product that is required to kill bacteria. This is the cheapest easiest product to get your system up and going, you can convert to tablets or a stabilized bromide product after startup.

- One LakeWood 140 Cooling Tower Controller - You will need to set the controller to feed and bleed the cooling tower water to maximize cycles and to minimize chemical usage rates. An optional dual biocide water treatment can be implemented after startup. This is model 1239597 (which is board mounted unit that has the flow assembly on the left).

- One 1167435 Cooling Tower Blowdown Valve (1" NPT) - This will be required when the cooling tower calls to release cooling tower water.

- Two Stenner 45MHP10 Adjustable Head Pumps - One pump is required for the corrosion/ scale prevention chemical and for the biocide. Each pump is rated to 100 psi, which should be enough to feed the chemical into the system. The ideal spot to feed the chemical is into the return header of the cooling tower. These Stenner Pump kits come with chemical injection valves that will allow for a quick injection of each chemical into the sidestream water loop that is used to monitor the cooling tower conductivity.

- One complete CWTK-200 Cooling Water Treatment Test Kit. This kit contains every test you will need to set up and fine tune your water treatment program.

- One Chemical Metal Test Station Cabinet - You need to keep your test kits and lo sheets in one clean location. This test kit is ideal for cooling towers. Items in the photo are not included.

55-gallon Product Removal

For easy product removal, consider adding a 55-gallon drum dolly to disperse your Isothiazolin from 2" bung faucets into 5-gallon pails, a hand pump, or drum pump.

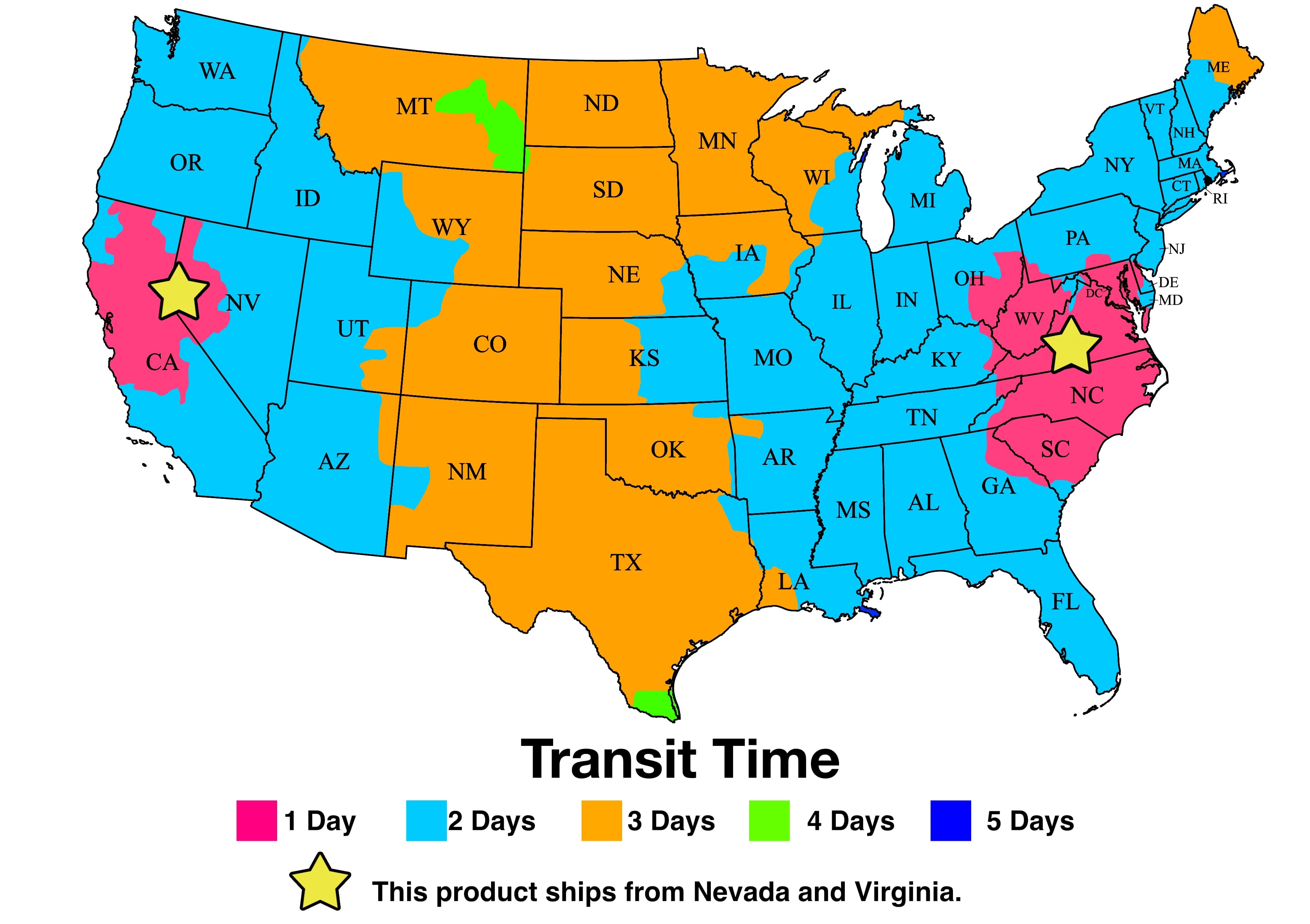

The raw materials for this product is in stock, but it is manufactured to order per ISO specifications. Lead time on production is 4 to 7 days. See transit times map below: Free shipping transit time in business days as of May 2023 (After Production).

Remember production time is 4 to 7 days. This map is transit time. You will receive your tracking number within a week after ordering.

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequently Asked Questions

- What amount of Isothiazolin do I need to put in a 300 gallon system that is made of stainless steel pipe and copper?

- The recommended Isothiazolin feedrate is 60 to 100 ppm dosed into the recirculating water. That's 7.5 to 12.5 oz per 1000 gallons.

- Can this product be shipped overnight to Florida?

- No, this is a hazmat-shipped product, and it is required to ship ground only. Shipping lead time is roughly 3 to 5 days, and it would take 2 days to reach Florida.

- We have a closed loop chill water system showing "Light" Mold on dip slides purchased from Chemworld. The system is approximately 1800 gallons of 33% ethylene glycol. Is Isothiazolin our best choice to reduce the mold in the closed loop system?

- No, we recommend to slug feed Gluteraldhyde at 100 ppm dosage.

|

|

|

|

|

|

|