|

|

|

|

Boiler ChemicalChemWorld 1194 is an all-in-one all polymer internal treatment product. ChemWorld 1194 includes a polymer for deposit control, an alkalinity builder for maintaining the boiler alkalinity, and sulfite for removing oxygen from the boiler water. ChemWorld 1194 does not include neutralizing amine which, if required, should be fed in combination with this product to maintain condensate quality. ChemWorld 1194 is typically used in systems with make-up water that has not been softened. Ideally, we always recommend installing a softener if possible.

ChemWorld 1194 is also used:

- For gradual removal of existing boiler scale. (Install a softener before using. If you do not stop hardness from entering the boiler, the polymer can not dissolve the existing scale.)

- This product is approved for USDA and FDA plants such as Breweries, Dairies, Bakeries, Beverage facilities, etc.

Chemistry Blend:

How to use:

ChemWorld 1194 is an all-in-boiler chemical. They are designed to make boiler chemical feeding and testing easy.

- Download our boiler testing logsheet and use it as a reference.

- Feed the chemical as far back into your steam boiler system (into the feed water tank, DA tank, or feed water line). This will ensure the metal as far back in the system is protected against corrosion.

- Keep a minimum of 20 ppm of sulfite residual (or use ASTM standards) on all active and idle boiler systems to reduce the risk of oxygen corrosion within your boiler. If you have excess product, it will raise your conductivity levels but will have no adverse effect on your boiler. You are just wasting chemical, water, and thermal energy within the water.

- If your boiler conductivity is too low, you are probably blowdown to much water or grossly overfeeding the chemical. Reduce blowdown and reduce chemical dosage and wait a few days. Allow the water to cycle up again within the boiler. Remember the purpose of your steam boiler system is to reuse water. Target a conductivity of 2,000 to 3,000 umhos (most steam boilers). For mid to large size steam boilers, we always recommend automation with a LakeWood Conductivity Controller. Using a Myron Meter is an easy way to verify your conductivity of your controller and boiler water.

- This chemical will add additional conductivity to your boiler water. Overfeeding will have no adverse effect on the boiler, but it will waste chemicals and you will blowdown excess water. Conductivity is a measurement of dissolved solids, dissolved gases, and suspended solids.

- Add more product as needed based on sulfite residual in your boiler water, but remember to keep your conductivity in range or your sulfite reading will be irrelevant. Use a Sulfite Test Kit to verify your residual.

- Monitor the boiler water Hardness as a reference.

- This product needs to be added daily, bi-weekly, or weekly depending on how your systems operate. In theory, the more frequently you add it, the less you will use.

- The purpose of the chemical is to prevent corrosion and scale prevention. As long as you have any sulfite in the boiler water, it means you have no dissolved oxygen in the boiler water.

- If you have any other questions, please email us at [email protected]. Remember to keep it simple. This is an easy boiler chemical to use as long as you get it into the system, you maintain proper conductivity levels within the boiler, you have a good operating softener, and you periodically check that sulfite is in the boiler. Do not over complicate it.

For new steam boiler startups, consider purchasing our Steam Boiler Startup Kit.

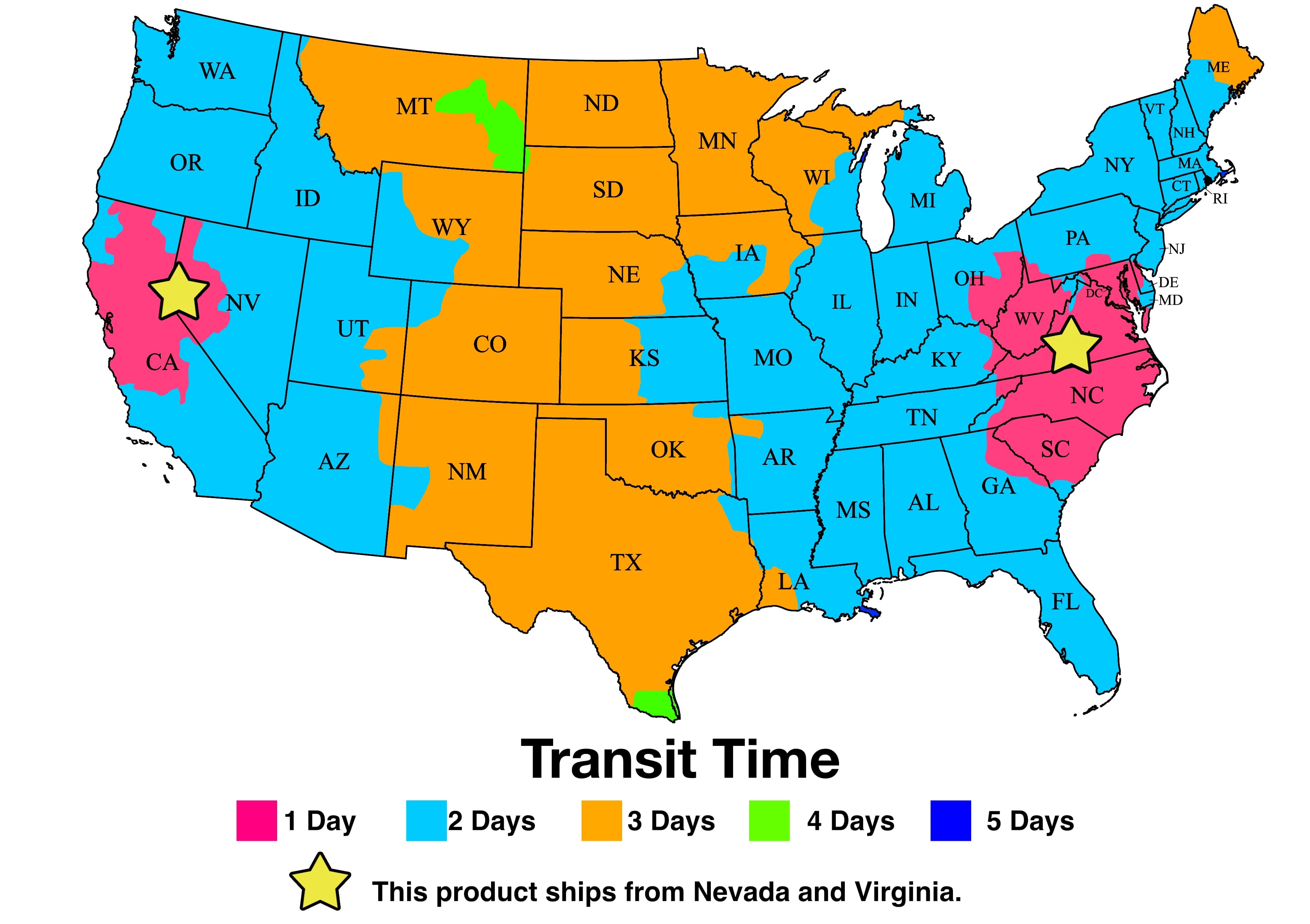

This product is manufactured to order per ISO specifications. Lead time on production is 4 to 7 days. Free shipping transit time in business days as of May 2023 (After Production).  Remember production time is 4 to 7 days. This map is transit time. You will receive your tracking number within a week after ordering. Remember production time is 4 to 7 days. This map is transit time. You will receive your tracking number within a week after ordering.

|

|

|

|

|

|

|