|

Cooling Water ChemicalThis is the most concentrated version of a cooling tower chemical you can purchase in liquid form. It is formulated for large cooling tower systems.

ChemWorld 1134 is a cooling water chemical product is used to minimize corrosion and to prevent scaling.

ChemWorld 1134 is a treatment program designed for recirculating cooling water systems operating at moderately scaling conditions. The product contains a combination of phosphonates, polymeric dispersants, and azole specifically formulated to minimize scale, general deposition and corrosion under moderate operating conditions. This product is designed to:

- Controls deposition and scale.

- Reduce water and treatment cost by enabling higher cycle operation.

- Operate at higher pH allows for minimum or no acid feed.

- Maintain organophosphonate residual between 10 to 15 ppm in the cooling water with a organophosphonate test kit.

- Feedrate is 100 to 300 ppm.

- Use rate is 0.9 to 3.6 gallons per 10,000 gallons of fresh make up water.

Chemworld 1134 mixture:

- Potassium Hydroxide (Cas No.1310-58-3)

- Aminotri(methylenephosphonic Acid) Potassium Salt (Cas No. 27794-93-0)

- Hydroxyethylidene Diphosphonic Acid, Potassium Salt (Cas No. 67953-76-8)

- Carboxylated Acrylic Polymer, Sodium Salt (Cas No. PROPRIETARY)

- Sodium Tolytriazole (Cas No. 64665-57-2)

For a less concentrated version or for lower water use cooling tower chemicals, please use our lower concentrated cooling tower chemical ChemWorld 1334.

For new cooling tower startups, consider our ChemWorld 101 Cooling Startup Kit. This kit includes the following:

- One 5 gallon pail of ChemWorld Q-ALK-PC - This product is required to clean the debris and greases prior to startup.

- One 5 gallon pail of ChemWorld 1334 - ChemWorld 1334 is scale and corrosion control cooling tower chemical. After startup, you can perform testing of your water hardness and alkalinity and we can tune in your exact chemical for long-term protection.

- One 5 gallon pail of ChemWorld 56 - ChemWorld 56 is a 12.5% sodium hypochlorite product that is required to kill bacteria. This is the cheapest easiest product to get your system up and going, you can convert to tablets or a stabilized bromide product after startup.

- One LakeWood 140 Cooling Tower Controller - You will need to set the controller to feed and bleed the cooling tower water to maximize cycles and to minimize chemical usage rates. An optional dual biocide water treatment can be implemented after startup. This is model 1239597 (which is board mounted unit that has the flow assembly on the left).

- One 1167435 Cooling Tower Blowdown Valve (1" NPT) - This will be required when the cooling tower calls to release cooling tower water.

- Two Stenner 45MHP10 Adjustable Head Pumps - One pump is required for the corrosion/ scale prevention chemical and for the biocide. Each pump is rated to 100 psi, which should be enough to feed the chemical into the system. The ideal spot to feed the chemical is into the return header of the cooling tower. These Stenner Pump kits come with chemical injection valves that will allow for quick injection of each chemical into the sidestream water loop that is used to monitor the cooling tower conductivity.

- One complete CWTK-200 Cooling Water Treatment Test Kit. This kit contains every test you will need to set up and fine tune your water treatment program.

- One Chemical Metal Test Station Cabinet - You need to keep your test kits and lo sheets in one clean location. This test kit is ideal for cooling towers. Items in the photo of test kit not included.

This product is manufactured to order per ISO specifications. Lead time on production is 4 to 7 days.

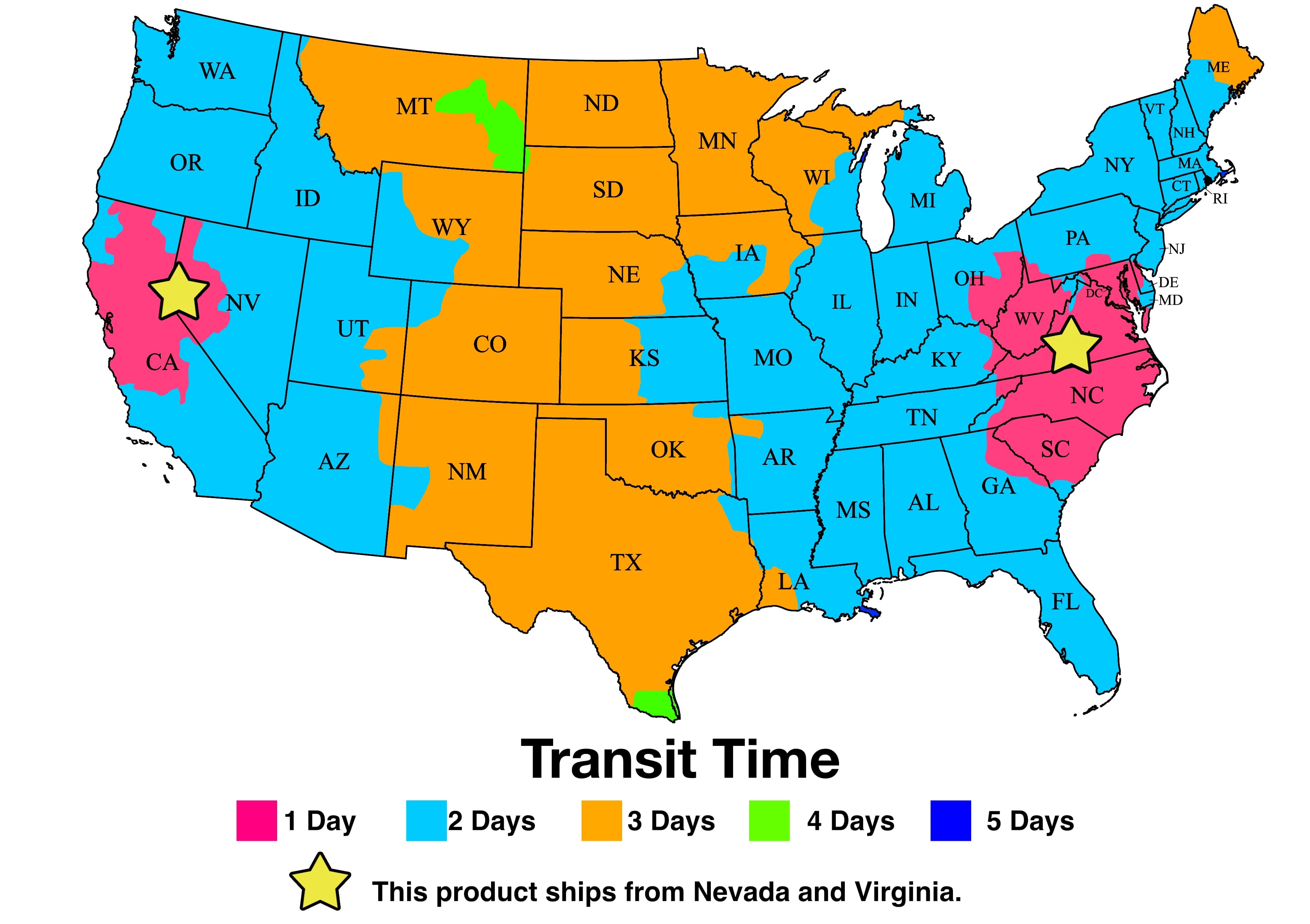

Free shipping transit time in business days as of May 2023 (After Production).

Remember production time is 4 to 7 days. This map is transit time. You will receive your tracking number within a week after ordering.

|

|

|